Baldor Bench Grinder Buying Guide

Bench grinders are a very powerful, useful, and unfortunately an often misused tool. You can use one to sharpen a lawnmower blade, return the cutting edge to a chisel, polish wood, or even grind gemstones to shape, among countless other uses. They can do just about anything from fine finishing work, to lopping off large amounts of material very quickly, to cutting, to polishing wood, gemstones, or metals, and they come in a range of sizes from small models all the way to larger machines designed for heavy-duty shop use.

Industry Best Bench Grinders

When it comes to bench grinders, Baldor is the top name in the industry. As a part of ABB Group, they are a reliable company, making a very wide selection of high-quality electric motors, sanders, buffers, polishers, and above all: grinders. Their grinders are famous for being constructed of a high-quality material, having long lifespans, and being very quiet in use.

Choosing a Baldor Bench Grinder

Bench grinders are pretty simple as far as tools go, but there are a lot of small distinctions between the various designs, in order to cater to the needs of, all of whom will need their machines to do slightly different work. While the basic construction of all grinders is very similar, there are several considerations that must be made while selecting which model is best for you.

How Will You Use It?

Like any other tool, the way you use the grinder will be the most important determining factor in which model you will end up buying. Baldor primarily makes industrial-grade machines, so they will be durable and ready to withstand strenuous use in high-demand environments such as auto shops. Whether you will be using a wire wheel to clean the rust off car fenders or sharpening chisels for a wood shop, there is a grinder for you. Grinders are also popular tools for polishing purposes, and there are cotton buffing wheels that can be attached to the spindle that leverage the high speed for a perfectly smooth finish. Having a rough idea of how it will be used will determine the size, speed, and power that will work the best for you.

Wheel Diameter

Bench grinders accept a predetermined wheel size, so it is important to know how to choose which size you need. The majority of grinding tasks can be accomplished with a small grinder, such as sharpening blades or shaping smaller chunks of metal. On the flip side, if you are planning on working on larger pieces, or are setting up a shop where metalwork will be commonplace, you will likely require a larger model. The bigger diameter will allow more space for you to maneuver and work efficiently, and there will be  more surface area on the wheel to work with.

more surface area on the wheel to work with.

To paint a picture, restoring the edge on a pocket knife blade can probably be done on a 6″ stone without any trouble, but you might feel a little cramped if you tried to use that same wheel to scrub the rust off a car fender before welding.

Buffing and polishing jobs are also a common use for grinders, and in some cases, smaller wheels can greatly restrict the scope of those tasks, meaning a wheel with a larger capacity would be a must.

Power Supply

Different grinders will have varying power needs in order to operate. The amount of power needed generally hinges on the size of the machine, with smaller tools needing lower voltage than their more sizable counterparts. Since larger tools are more likely to encounter heavier workloads, many of the larger models are engineered in a way that they plug into either a standard outlet, but if some additional push is needed they can also tap into a more powerful 230V outlet like the one your laundry machine uses.

On the subject of electricity, it is important to note that since larger grinders require more power to spin, they also draw a much larger amount of current. 6” grinders generally have 3.1 amp motors, while the motor turning an 8” stone can pull up to 4.8 amps. If you need to stay on a budget, make certain to remember to check the amperage of your selection before your utility bill skyrockets.

Wheels Included

The more compact models typically come with wheels included in the package, and they are either two stone wheels or one stone wheel and a wire brush wheel. While additional wheels can be bought separately, if you want to use your new grinder right out of the box, you will need to know which set you will be receiving so that you can get right to work. The combinations will either be 60 grit and 30 grit grinding wheels, or a 36 grit stone wheel and a .014 wire brush. If you plan on doing mostly sharpening of blades, chisels, and other applications that will require more grinding work, the set of two-wheels would be a smarter choice. On the other hand, the wire brush is able to wipe rust right off of metal to prepare them for painting, welding, or polishing.

For those who really want to make the most of their limited space, the model 248-181TD pulls double-duty with a 36-grit grinder wheel on one side and a belt sander on the other half. While this means you may have to switch grinder wheels more frequently, the versatility of sanding without investing in an additional single-purpose machine is an incredible deal. It also allows for work on wood and other softer materials that can’t handle the heat of the grindstone.

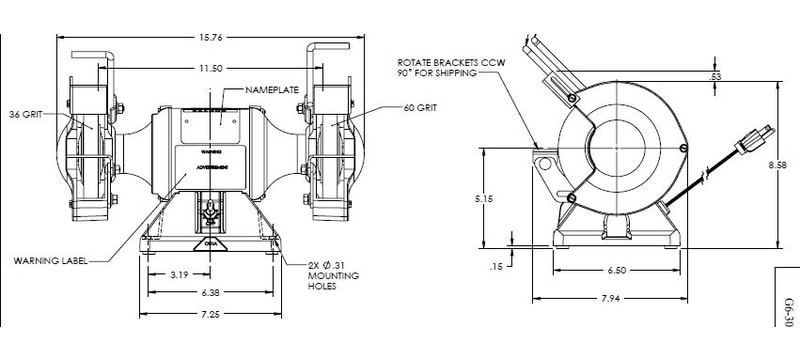

Machine Dimensions

A larger grinder will take up more floor space than a small one. This might seem obvious, but if you have a small garage to work in, it might be wiser to look into a more compact tool that can be tucked away when not in use, rather than a heavier model that requires a dedicated corner of your already-crowded workbench. For safety purposes, bench grinders should always be secured down before any work is done, and the smaller configurations can be attached to a mobile base and clamped to a bench while remaining light enough that moving them is simple. The largest grinders can weigh well over 100 lbs, so moving them around frequently will not really be as practical as bolting them down or attaching them to a pedestal base.

Wheel Speed

Baldor grinders will only spin at one of two preset speeds, either 1800 or 3600 RPM, which is determined by the factory. Only the larger-size machines will spin at the slower setting, due to the extra power needed to spin the wheel as it increased in size and weight. When sharpening wood-carving chisels, a faster grinding wheel will generate more heat, and from there it is easy to burn the metal and lose the hard outer layer needed to keep a sharp point. Slower wheels can still burn tools, but it offers much more control to the user, and can potentially prevent destroying costly utensils. Another benefit of slower speeds is that the wheels are subjected to less stress and will last longer, which can save you money and time in the long run.

Baldor grinders will only spin at one of two preset speeds, either 1800 or 3600 RPM, which is determined by the factory. Only the larger-size machines will spin at the slower setting, due to the extra power needed to spin the wheel as it increased in size and weight. When sharpening wood-carving chisels, a faster grinding wheel will generate more heat, and from there it is easy to burn the metal and lose the hard outer layer needed to keep a sharp point. Slower wheels can still burn tools, but it offers much more control to the user, and can potentially prevent destroying costly utensils. Another benefit of slower speeds is that the wheels are subjected to less stress and will last longer, which can save you money and time in the long run.

A Few Other Things to Think About

We have covered the most important pieces of information that you will need to know, but there are still plenty of other models, and you could still be a little lost. If you’re still having a hard time picking one grinder over another, here are a few final tiebreakers to help you make up your mind.

Power Cord

As the motors get larger and higher voltages are called for, power cords are not always included with the grinder. In these cases, the user is required to wire them up to their desired power source. For all 6 or 7-inch models, this is not a cause for concern, as the only types that do not come packaged with a cord are 248-181TD, 1021W, and 1022W.

Dust Port

Collecting discarded material can become a serious issue with larger grinders, as they can be carving off far more material than smaller designs. Because of this, having the option to connect a vacuum can be important, and all 8″ designs and larger have built-in dust ports on the wheel guards. A small selection of 6″ and 7″ grinders also feature exhaust ports, this is denoted by models numbers ending in the letter “E” (the “E” stands for exhaust, to make it easy to remember).

Color

Several models have two colors to choose from, either red or blue. The distinction is entirely superficial, and the interior components are completely identical. There is a clever trick to remember which model number indicates which color: it will either end in the letter “B” for blue or “R” for red. It’s a rather clever system if you ask us.

Final Thoughts

No matter what your needs are, Baldor has a bench grinder that you will love. Be sure to know the wheel size, wheel speed, voltage, and what wheels come included in the package. It will be a tool that you keep in your workshop for many years, so take the time and figure out exactly what you need before committing. Consider the space you have available, how frequently you will be using it, the size pieces you will be working with, and the available power in your place of work. Grinders are versatile and powerful tools, and so long as you have done your research, they are very fun to use. As a guide to help you visualize the options Baldor has to offer, we have created a small table with basic information about each model.

| Model | Wheel Diameter (In.) | RPM | Voltage (V) | Wheel Included | Color |

|---|---|---|---|---|---|

| 602E | 6 | 3600 | 115 | 36 grit wheel and wire brush | Blue |

| 612B1 | 6 | 3600 | 115 | 30/60 grit wheels | Blue |

| 612R | 6 | 3600 | 115 | 30/60 grit wheels | Red |

| 612E | 6 | 3600 | 115 | 30/60 grit wheels | Blue |

| 662B | 6 | 3600 | 115 | 36 grit wheel and wire brush | Blue |

| 662R | 6 | 3600 | 115 | 36 grit wheel and wire brush | Red |

| 712B | 7 | 3600 | 115 | 30/60 grit wheels | Blue |

| 712R | 7 | 3600 | 115 | 30/60 grit wheels | Red |

| 712E | 7 | 3600 | 115 | 30/60 grit wheels | Blue |

| 762 | 7 | 3600 | 115 | 36 grit wheel and wire brush | Blue |

| 762R | 7 | 3600 | 115 | 36 grit wheel and wire brush | Red |

| 8100W | 8 | 1800 | 115/230 | 30/60 grit wheels | Blue |

| 8107WD | 8 | 3600 | 115/230 | 30/60 grit wheels | Blue |

| 812RE | 8 | 3600 | 115/230 | 30/60 grit wheels | Red |

| 8250W | 8 | 3600 | 115/230 | 36 grit wheel and wire brush | Blue |

| 248-181TD | 8 | 3600 | 115/230 | 36 grit wheel, 80 grit sanding belt | Blue |

| 1021W | 10 | 1800 | 208-230/460 | 30/60 grit wheels | Blue |

| 1022W | 10 | 1800 | 115/230 | 30/60 grit wheels | Blue |